Diecast car restoration is a passion that combines the mechanical love of automobiles with the meticulous artistry of model making. There’s something enchanting about the transformation of a battered model into a gleaming, personalized piece of automotive history. In this comprehensive guide, we'll delve into the nitty-gritty of diecast car restoration, exploring the process step-by-step, from initial disassembly to the finishing touches. By the end, you'll have the knowledge and inspiration to start restoring your favorite models and keep them in pristine condition.

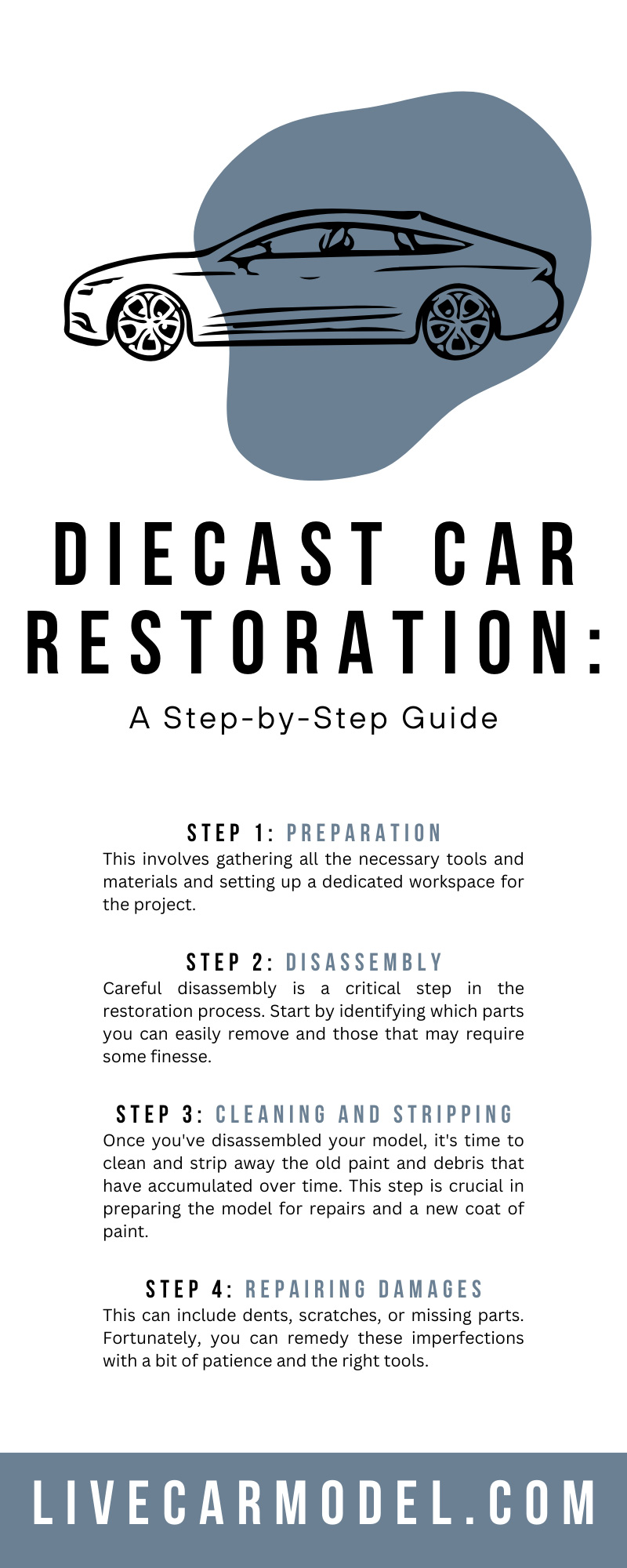

Step 1: Preparation

Before you start disassembling your diecast model cars, it's crucial to be well-prepared. This involves gathering all the necessary tools and materials and setting up a dedicated workspace for the project. The right preparation ensures a smooth restoration process and helps you avoid common pitfalls that could affect the quality of your work.

Gathering Necessary Tools and Materials

Begin by making a list of tools you'll need. This can include screwdrivers of various sizes, tweezers for precision work, and putty for repairs. You'll probably also need tweezers, a magnifying glass, paints, brushes, primer, and super glue. Be sure to research the right types of paints and primers for your specific diecast model, as using incorrect materials can compromise the restoration's longevity and appearance.

Setting Up a Workspace

Choose a well-lit area with plenty of ventilation. Don't underestimate the importance of good lighting that lets you see fine details clearly. Additionally, set up a workbench or table dedicated solely to your diecast restoration work. This will allow you to keep all your materials and tools organized and prevent them from being used for other purposes, which could lead to contamination or loss.

Step 2: Disassembly

Careful disassembly is a critical step in the restoration process. Start by identifying which parts you can easily remove and those that may require some finesse.

A few tips for disassembly include:

- Work on a soft surface to avoid part loss or damage from rolling.

- Keep track of screws and other small items by placing them in labeled containers.

- Use appropriate tools to avoid damaging the model or its parts.

Remember to use a systematic approach, taking note of the arrangement and orientation of each part as you remove it. Consider photographing or labeling each part to aid in reassembly later.

Step 3: Cleaning and Stripping

Once you've disassembled your model, it's time to clean and strip away the old paint and debris that have accumulated over time. This step is crucial in preparing the model for repairs and a new coat of paint.

Removing Old Paint

You can strip the old paint using methods such as:

- Chemical paint strippers: Effective but require careful handling to avoid damage to the model or your skin.

- Sandblasting: An aggressive approach better suited for larger models with thick paint layers.

- Sanding: Use fine-grit sandpaper to eliminate the paint gradually, ensuring you don't sand down the model's details or surface.

Each method has its benefits and drawbacks, so choose the best fit for your items and setup.

Deep Cleaning

Use a mixture of warm, soapy water to remove stubborn dirt and debris. You may need to soak the parts for a significant time to loosen tough grime. Avoid abrasive cleaning methods that could scratch the diecast or remove fine details.

Step 4: Repairing Damages

Next, it's time to assess the condition of your diecast model and address any damage it might have sustained. This can include dents, scratches, or missing parts. Fortunately, you can remedy these imperfections with a bit of patience and the right tools.

Fixing Dents and Scratches

Use a putty appropriate for metal surfaces to fill in dents and scratches. Once the putty dries, sand it lightly to achieve a smooth surface. For deeper dents, you may need to apply multiple layers of putty, then sand each layer as it dries.

Filling in Gaps or Missing Parts

If your model has missing parts, you can fashion replacements from scratch using putty or plastic moldings or source spare parts from other diecast models or custom parts suppliers. Remember to maintain the scale and proportions of the original model when making or sourcing replacements.

Step 5: Priming and Painting

Now that you've cleaned and repaired your diecast model, it's time to prime and paint. Priming creates a uniform surface for the paint to adhere to, while painting gives the model its new, vibrant look.

Applying Primer

The primer helps to smooth out imperfections and provides an even base for the paint. Apply several thin coats of primer, allowing each layer to dry before adding the next. This builds up coverage without obscuring details.

Choosing the Right Paint

You can use various types of paint, including acrylics, enamels, and lacquers. Each has its benefits and application techniques, so choose one that suits your skill level and desired outcome. High-quality automotive paint gives a durable, glossy finish, similar to what you'd find on real cars.

Painting

When painting your diecast model, remember, thin layers are best for a professional finish. Thick paint can run or obscure details, so allow each coat to dry before applying the next. It's important to ensure a dust-free environment since even tiny particles can cause imperfections in your finish. Remember to wear protective equipment, such as masks and gloves, to protect yourself from fumes and chemicals, work in a well-ventilated area or use a fume hood to disperse paint vapors.

Step 6: Detailing and Decals

Details and decals are the little touches that bring your diecast model to life. Pay attention to the small features that make the car unique and add character.

Adding Fine Details

Use fine brushes and steady hands to paint small details like headlights, taillights, and emblems. Small details can make a big difference in the realism of your restoration.

Applying Decals

Decals can be challenging to apply, but they're worth the effort for the authentic look. Use a decal softener to help decals conform to the model's shape and eliminate air bubbles. Finally, seal the decals with a clear coat to protect them and give a seamless finish.

Step 7: Reassembly

With your model cleaned, painted, and detailed, it's time to reassemble it. Refer to the labels or photos you took during disassembly to ensure you reassemble parts in the correct order.

Organizing Parts

Before you start reassembling, organize your parts and tools to make the process more efficient. Ensure all parts are clean and free from dust or debris that could affect the fit or finish.

Ensuring Proper Alignment and Fit

Take your time to ensure that each part is aligned and fits correctly. This can be a difficult process, especially with smaller, more intricate models, but the final result is worth the effort.

Breathe New Life Into Your Collection

For those looking for a rewarding hobby that allows you to combine craftsmanship with a deep love for automobiles, this step-by-step restoration guide serves as your roadmap to breathing new life into your diecast car collection. The satisfaction of seeing a once-neglected model transformed into a stunning piece of automotive history is unparalleled. So get your supplies and get to work. Your next-level collection is waiting!